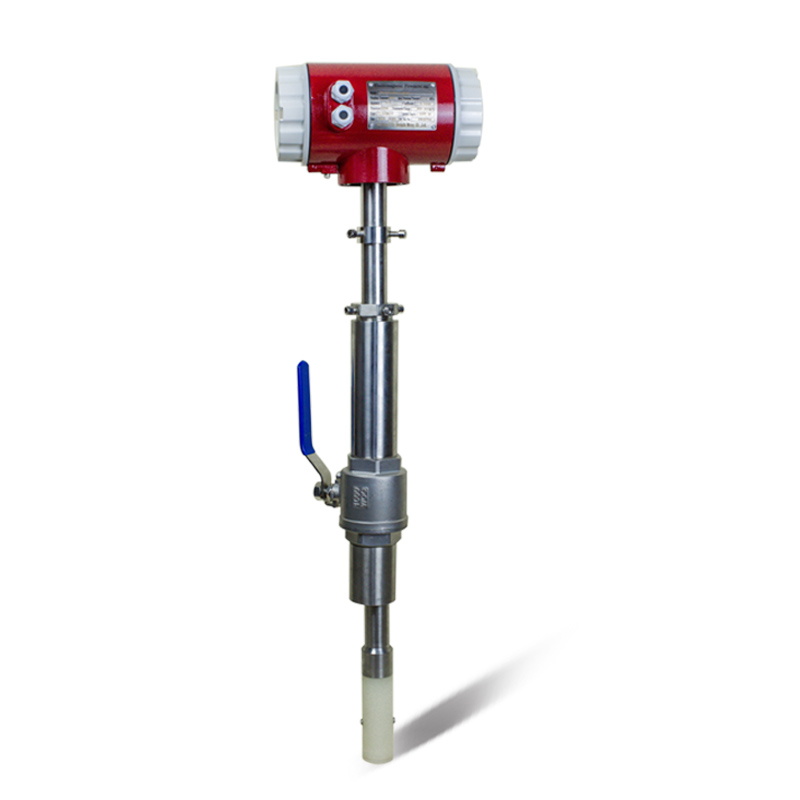

Insertion Type Electromagnetic Flow Meter

The plug-in electromagnetic flow meter measures the volume flow of various conductive liquids in the pipeline. It is widely Plug in flowmeter is a kind of flowmeter divided by structure, which includes various flowmeters with different working principles. Plug in flowmeter has made great progress, and from the perspective of the development trend of the whole flowmeter, it has strong vitality and occupies an important position in many flowmeters.

Product features

♦ The plug-in electromagnetic flowmeter has the advantages of simple installation and favorable.

♦ Low frequency ternary rectangular wave constant current excitation is not affected by power frequency and various on-site stray interference, and its operation is very stable and reliable.

♦ New technology of non-uniform magnetic field and special magnetic structure are adopted. The magnetic field is stable, and the volume and weight are greatly reduced, making the flowmeter small and lightweight.

♦ Special electronic circuit shall be adopted, with the function of automatic reset of air traffic control.

♦ The measuring range can be modified online according to the actual needs of users on site.

♦ There are no movable parts and flow blocking parts. There is almost no additional pressure loss in the measurement.

♦ The measurement results are independent of physical parameters such as flow velocity distribution, liquid pressure, temperature, density and viscosity.

♦ It is easy to use. After installation, it is only necessary to connect the power supply and output standard signals without any other operation, which is convenient for non professionals to use.

Product Parameters:

Nominal diameter | DN15~DN2000 |

Accuracy | ±0.5% |

Measurement range (flow rate) | 0.01m/s~15m/s |

Conductivity of medium | more than 5μS/cm |

Nominal pressure | 0.6MPa, 1.0MPa, 4.0MPa |

Protection grade | IP65, IP67, IP68 |

Electrode material | Stainless steel 316L, Hastelloy B, Hastelloy C, Titanium alloy, Tantalum alloy, Platinum-iridium alloy, Stainless steel-coated tungsten carbide and other special material. |

Lining material | Neoprene, Polyurethane rubber, natural rubber, nitrile rubber, Teflon(PFA), Polytetrafluoroethylene (PTFE), fluorinated ethylene propylene (FEP OR F46), ceramics. |

Connection | Flange connection [GB/T9119-2010 standard] |

Ambient temperature | -10℃~50℃ |

Power supply | AC220V/DC24V/DC3.6V |

Signal output | Analog 4mA-20mA, 0Hz~ 5 KHz frequency, two alarm outputs: high limit alarm and low limit alarm |

Communication | RS485, RS232, MODBUS, HART, PROFIBUS-DP (OPTIONAL) |