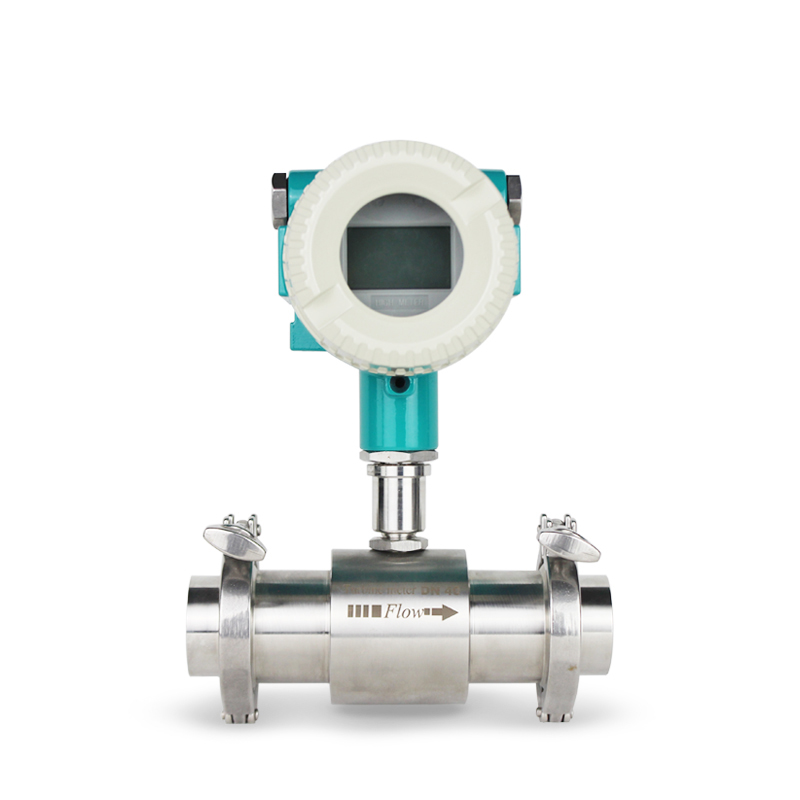

Tri-Clamp Turbine Meters Water Flow Meter

The clamp-type turbine flowmeter is a new generation of turbine flowmeter with a simple structure, light weight, high accuracy, good reproducibility, sensitive response, convenient installation, maintenance, and use, which is widely used to measure the corrosion of stainless steel 1Cr18Ni9Ti, 2Cr13, corundum Al2O3 and hard alloy in closed pipes, and is free of fibers, particles, and other impurities.

Product specifications:

High precision, generally up to ± 1% R, ± 0.5% R, high precision type up to ± 0.2% R;

Good repeatability, short-term repeatability can reach 0.05%~0.2%;

Output pulse frequency signal, suitable for total metering and computer connection, no zero drift, strong anti-interference capability;

A high frequency signal (3-4kHz) can be obtained with strong signal resolution;

Wide range, up to 1:20 for medium and large calibers and 1:10 for small calibers;

Compact and light structure, convenient installation and maintenance, and large circulation capacity;

It is suitable for high voltage measurement. There is no need to open a hole in the meter body, and it is easy to make a high voltage instrument;

There are many types of special sensors, which can be designed as various special sensors according to the special needs of users;

It can be made into a plug-in type, suitable for large diameter measurement, with small pressure loss, low price, and easy installation and maintenance.

Technical parameter:

Measuring medium | No impurities, no strong corrosivity, low viscosity liquid | |||

Executive standards | Turbine flow sensor (JB/T9246-1999) | |||

Verification regulation | Turbine flowmeter (JJG1037-2008) | |||

Instrument diameter and connection mode | Flange connection type | DN15-DN200 | ||

Threaded connection type | DN4-DN50 | |||

Clamp connection type | DN25-DN50 | |||

Flange standard | General standards | GB/T9113-2000 | ||

Other standards | International Pipe Flange Standard | Such as German standard DIN, American standard ANSI, Japanese standard JIS | ||

Domestic pipe flange standards | Such as the standards of the Ministry of Chemical Industry and the Ministry of Machinery | |||

Thread size | General specifications | Inch pipe thread (external thread) | ||

Other specifications | Internal thread, NPT thread, etc | |||

Accuracy class and corresponding repeatability | Accuracy class | ±1%R | ±0.5%R | ±0.2%R (To be customized) |

Linearity | ≤0.15% | ≤0.1% | ≤0.03% | |

Range ratio | 1:10; 1:15; 1:20 | |||

Instrument material | 304stainless steel; 316stainless steel | |||

Temperature of measured medium (℃) | -20℃~+110℃ | |||

Verification conditions | Environment condition | Ambient temperature | 20℃ | |

Relative humidity | 65% | |||

Calibration device | Standard meter method liquid flow verification device | |||

Liquid flow verification device with static mass method | ||||

Use condition | Ambient temperature | -20℃~+60℃ | Relative humidity | 5%~90% |

Atmospheric pressure | 86Kpa~106Kpa | |||

Output signal | Pulse frequency signal | |||

Two wire 4-20mA DC current signal | ||||

485 communication | ||||

Power supply | 24V DC | |||

Transmission distance | ≤1000m | |||

Signal line interface | Basic type: Hesmann connector, explosion-proof type: internal thread M20 * 1.5 | |||

Explosion proof grade | Basic type: non explosion-proof product, explosion-proof type: Exd II CT6 Gb | |||

Degree of protection | IP65 | |||