2023-02-20

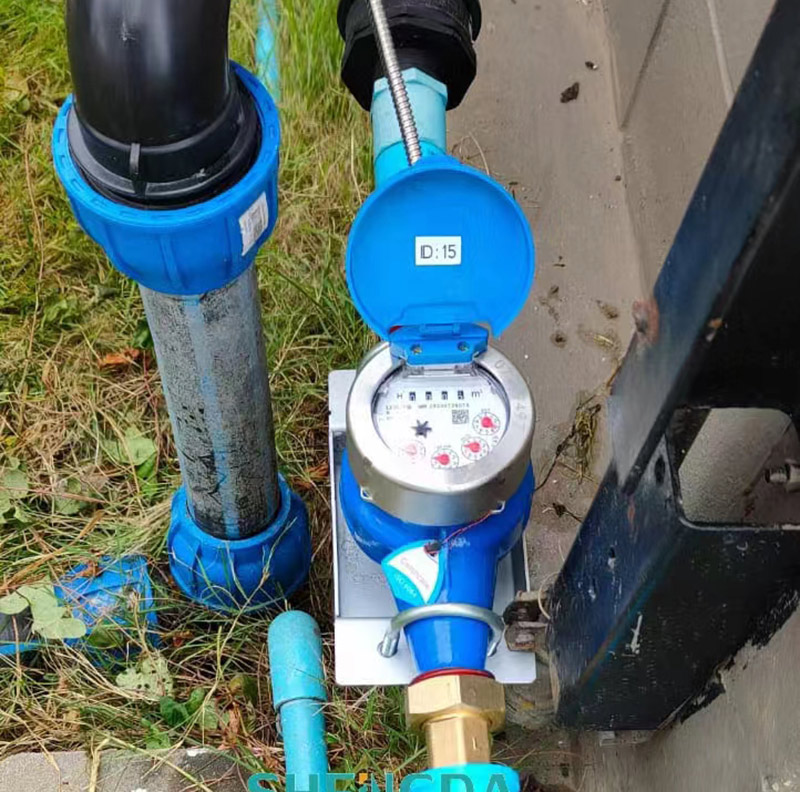

The severe winter has come. In order to ensure that your water life will not be affected by the severe winter, please pay more attention to the water supply facilities in your home during your busy schedule, and take thermal insulation measures for the water supply facilities in advance to avoid freezing damage in winter, which will affect your water use.Little knowledge of water antifreeze:1. Wearing clothes to prevent cold, the water meter and the exposed pipes, water supply equipment and other water facilities behind the water meter shall be wrapped with cotton and hemp textile for thermal insulation, and the water meter well shall be filled with necessary thermal insulation materials for thermal insulation.2. Close the windows to prevent cold. When the weather is cold, please close the windows of the balcony, kitchen, sanitary and other water rooms to ensure that the indoor temperature is above zero.3. Drip water to prevent cold. Users can turn on the faucet when the temperature is below - 5 ℃ to make the water drip into a line to prevent the pipeline from freezing. At the same time, users are invited to collect the outflow water to save water resources and avoid water waste.

4. Emergency measures: For frozen pipes, please cover them with hot towels and pour warm water to melt ice. Do not use open fire, because the current pipes are made of food-grade plastic materials. Even if the outer pipes are galvanized, there are plastic interlayer inside, and open fire will damage the pipes.

2023-02-20

The severe winter has come. In order to ensure that your water life will not be affected by the severe winter, please pay more attention to the water supply facilities in your home during your busy schedule, and take thermal insulation measures for the water supply facilities in advance to avoid freezing damage in winter, which will affect your water use.Little knowledge of water antifreeze:1. Wearing clothes to prevent cold, the water meter and the exposed pipes, water supply equipment and other water facilities behind the water meter shall be wrapped with cotton and hemp textile for thermal insulation, and the water meter well shall be filled with necessary thermal insulation materials for thermal insulation.2. Close the windows to prevent cold. When the weather is cold, please close the windows of the balcony, kitchen, sanitary and other water rooms to ensure that the indoor temperature is above zero.3. Drip water to prevent cold. Users can turn on the faucet when the temperature is below - 5 ℃ to make the water drip into a line to prevent the pipeline from freezing. At the same time, users are invited to collect the outflow water to save water resources and avoid water waste.

4. Emergency measures: For frozen pipes, please cover them with hot towels and pour warm water to melt ice. Do not use open fire, because the current pipes are made of food-grade plastic materials. Even if the outer pipes are galvanized, there are plastic interlayer inside, and open fire will damage the pipes.

2023-01-13

ApplicationMicro flow electromagnetic flow meter AMag Mini adopts the latest integrated circuit, signal processing technology andThe sensor is designed by manufacturing process, and is specially used for micro flow measurement of ultra small caliber.It can be used in chemical industry, food, medical treatment, environmental protection and many other fields.Features of micro electromagnetic flow meter: Compact design and low cost micro flow electromagnetic flow meter;Suitable for liquid with conductivity of 10uS/cm or above;Easy to install and maintenance free;The minimum flow can be as low as 5L/h;Optional integrated temperature sensor is provided to display the medium temperature;Counter with two-way measurement and independent counting;Intelligent ATC detection and judgment;PEEK lining and optional EPDM seals can be provided for sanitary measurement;No moving parts or mechanical wear;Threaded connection, easy to install and disassemble;It is easy to operate and can provide various outputs;DC24V power supply, with or without display screen. Technical parameters are as follows:1. Applicable diameter: DN3-DN202. Electrode material: 316L, HB, HC, Ti3. Lining material: PEEK4. Medium conductivity: more than 10us/cm, softened water more than 20us/cm5. Velocity range: 0.3m/s-10m/s6. Ambient temperature: - 10-60 ℃7. Measuring temperature: - 20-100 ℃8. Pressure: 0.6-1.6MPa9. Protection grade: IP65, IP67 (blind meter)10. Shell material: cast aluminum+stainless steel11. Connection method: thread 1/2, G3/4, NPT1/212. Output signal: 4-20mA, pulse/frequency, RS48513. Power supply: DC24V14. Current power consumption: lobule 150MA15. Boundary dimension: 150X100X70mmSpecial precautions for mini flow meter installationDuring horizontal installation: the display screen should be upward and parallel to the horizontal plane, so as to ensure that the signal electrode is in the same waterOn the plane. For horizontal installation, the display screen should not be installed perpendicular to the horizontal plane, so that the two signal electrodes are one on the otherWhen there are bubbles in the pipe, the measurement will be seriously affected.During vertical installation: the direction of flow direction shall be vertically upward, and the direction of water flow shall also be vertically upward, instead of vertically downward.

2023-01-13

ApplicationMicro flow electromagnetic flow meter AMag Mini adopts the latest integrated circuit, signal processing technology andThe sensor is designed by manufacturing process, and is specially used for micro flow measurement of ultra small caliber.It can be used in chemical industry, food, medical treatment, environmental protection and many other fields.Features of micro electromagnetic flow meter: Compact design and low cost micro flow electromagnetic flow meter;Suitable for liquid with conductivity of 10uS/cm or above;Easy to install and maintenance free;The minimum flow can be as low as 5L/h;Optional integrated temperature sensor is provided to display the medium temperature;Counter with two-way measurement and independent counting;Intelligent ATC detection and judgment;PEEK lining and optional EPDM seals can be provided for sanitary measurement;No moving parts or mechanical wear;Threaded connection, easy to install and disassemble;It is easy to operate and can provide various outputs;DC24V power supply, with or without display screen. Technical parameters are as follows:1. Applicable diameter: DN3-DN202. Electrode material: 316L, HB, HC, Ti3. Lining material: PEEK4. Medium conductivity: more than 10us/cm, softened water more than 20us/cm5. Velocity range: 0.3m/s-10m/s6. Ambient temperature: - 10-60 ℃7. Measuring temperature: - 20-100 ℃8. Pressure: 0.6-1.6MPa9. Protection grade: IP65, IP67 (blind meter)10. Shell material: cast aluminum+stainless steel11. Connection method: thread 1/2, G3/4, NPT1/212. Output signal: 4-20mA, pulse/frequency, RS48513. Power supply: DC24V14. Current power consumption: lobule 150MA15. Boundary dimension: 150X100X70mmSpecial precautions for mini flow meter installationDuring horizontal installation: the display screen should be upward and parallel to the horizontal plane, so as to ensure that the signal electrode is in the same waterOn the plane. For horizontal installation, the display screen should not be installed perpendicular to the horizontal plane, so that the two signal electrodes are one on the otherWhen there are bubbles in the pipe, the measurement will be seriously affected.During vertical installation: the direction of flow direction shall be vertically upward, and the direction of water flow shall also be vertically upward, instead of vertically downward.